SERVICES

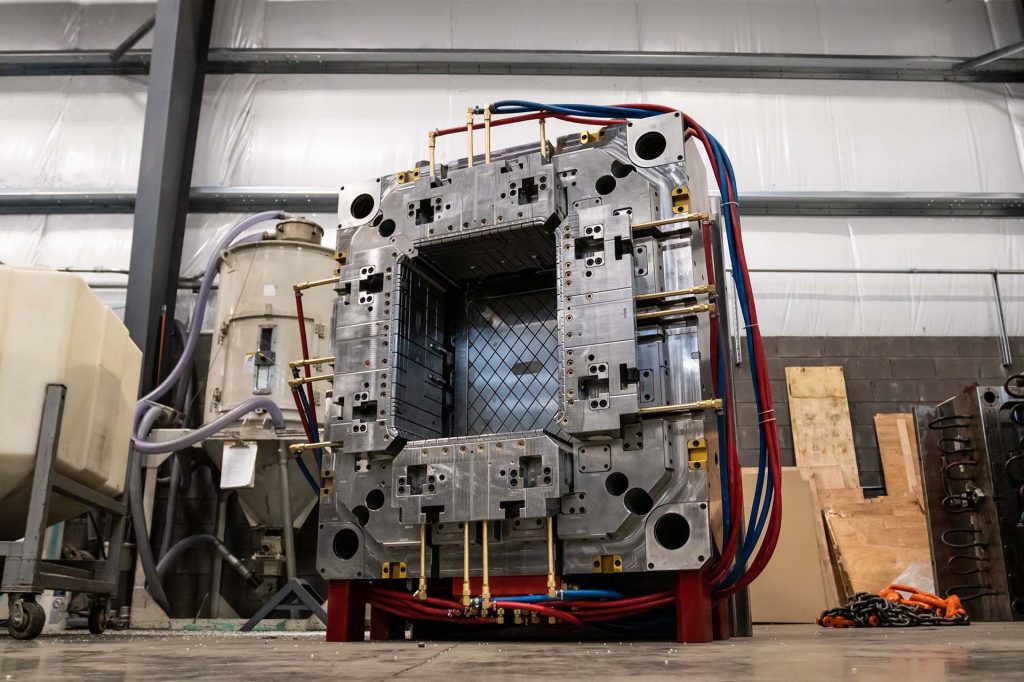

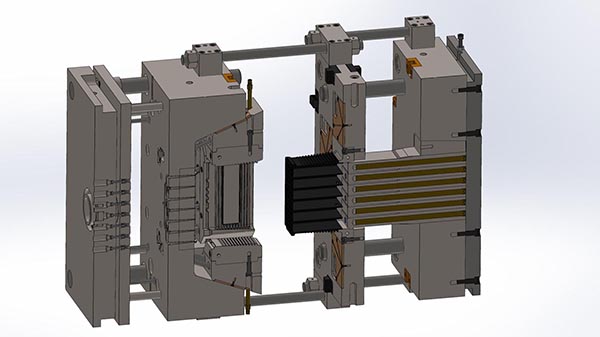

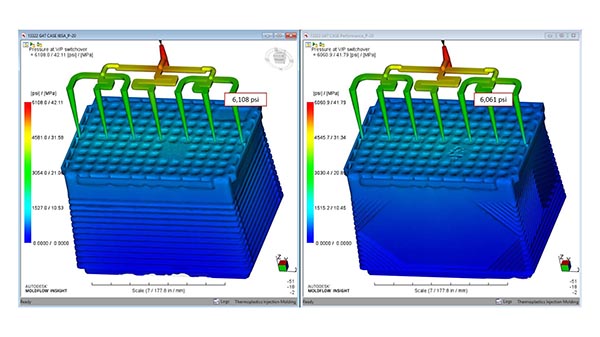

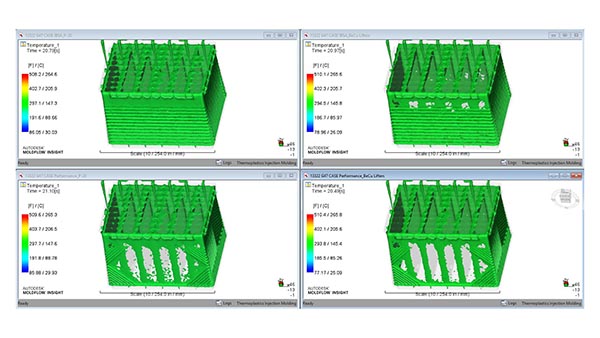

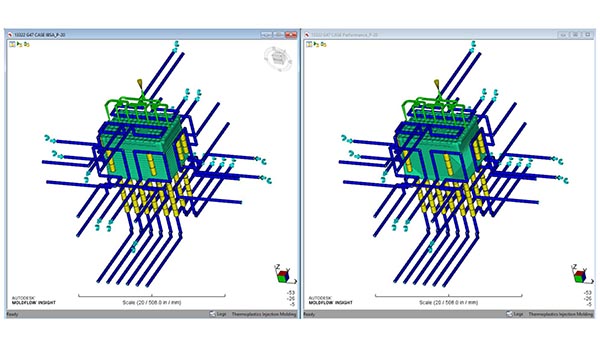

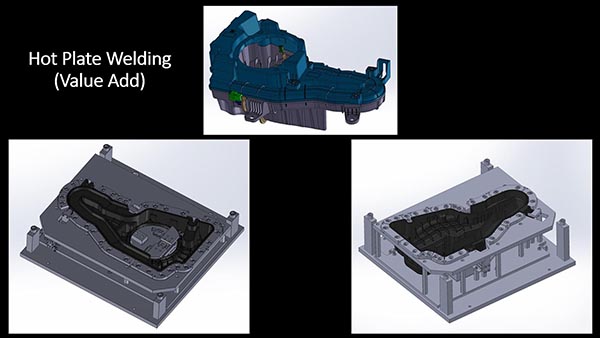

Venture Plastics is a full-service injection molder offering a wide array of value-added propositions. Our secondary operations include sonic welding, sub-assembly, screen printing, hot stamping, pad printing, decorating, and bar coding, ensuring comprehensive solutions for all your manufacturing needs. Our engineering team, with expertise in molding, tooling, product development, and materials, provides comprehensive project management from concept through production, seamlessly integrated with APQP processes. We also specialize in additive manufacturing for prototypes, tool build management, and leverage global tooling resources. Our design support services and extensive experience with various engineering resins are complemented by scientific molding technologies embedded in every mold and process. Our advanced engineering/CAD capabilities include SolidWorks, Pro/E, AutoCAD, Unigraphics, IGES, STEP, Parasolid, and Catia. Choose Venture Plastics for innovative, reliable solutions in injection molding and engineering services, ensuring the highest quality and efficiency for your projects.

Venture Plastics is a full service injection molder with many value add propositions.

SECONDARY OPERATIONS

- Sonic Welding

- Sub Assembly

- Screen Printing

- Hot Stamping

- Pad Printing

- Decorating

- Bar Coding

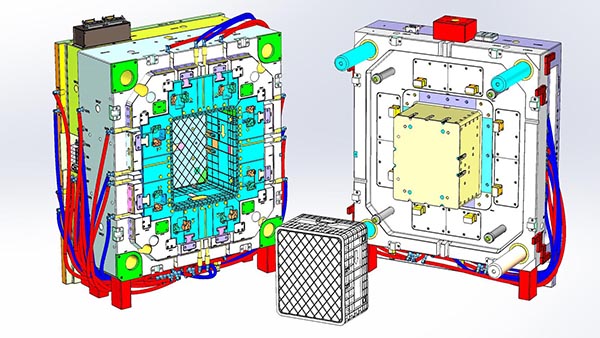

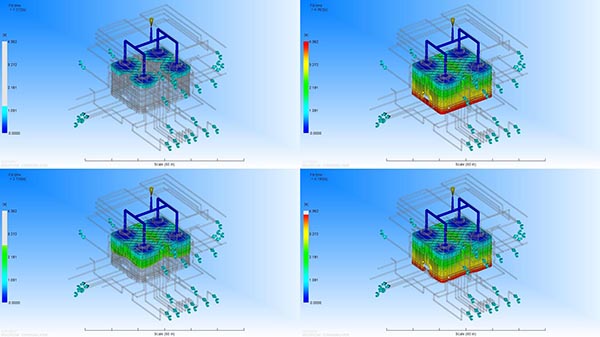

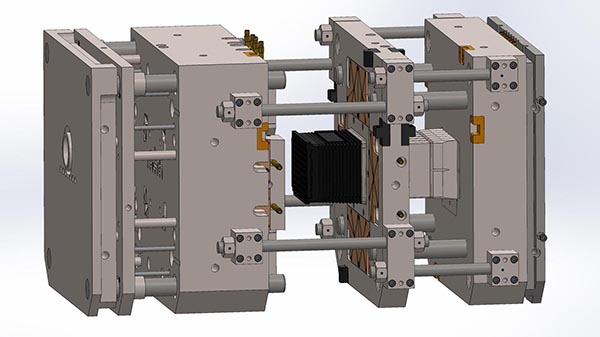

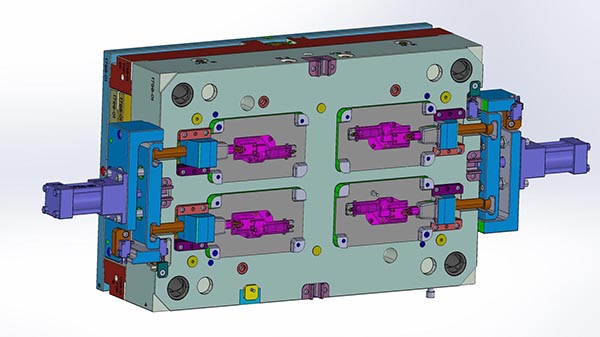

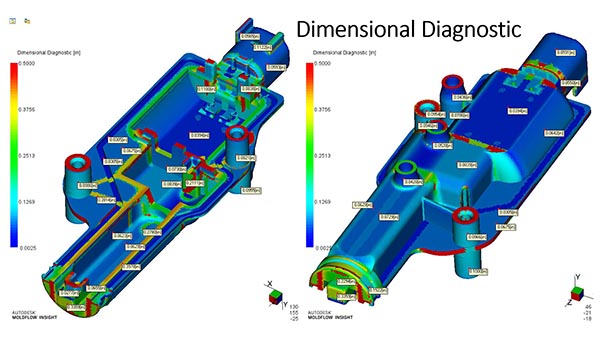

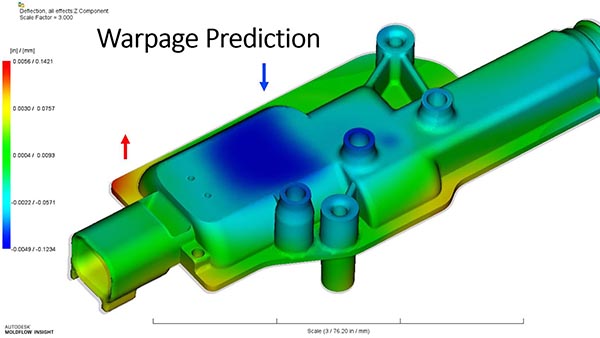

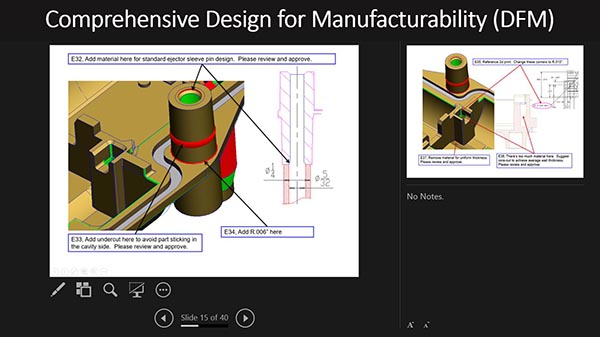

ENGINEERING

- Technical staff with expertise in molding, tooling, product development, and materials

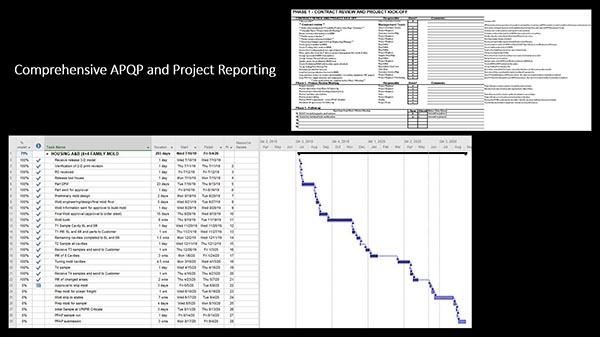

- Comprehensive project management from concept through production, integrated with APQP processes

- Additive Manufacturing for Prototypes

- Tool build management

- Global tooling resources

- Design support services

- Experience with a vast range of engineering resins

- Scientific molding technologies built into every mold/ process

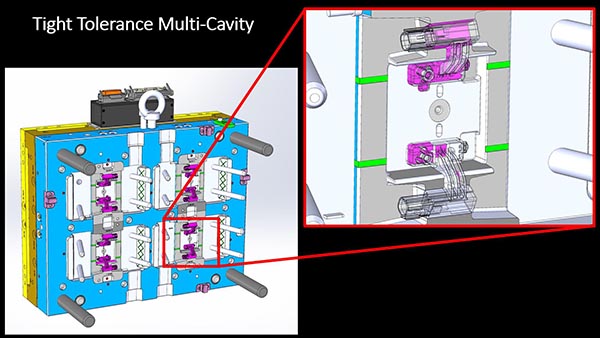

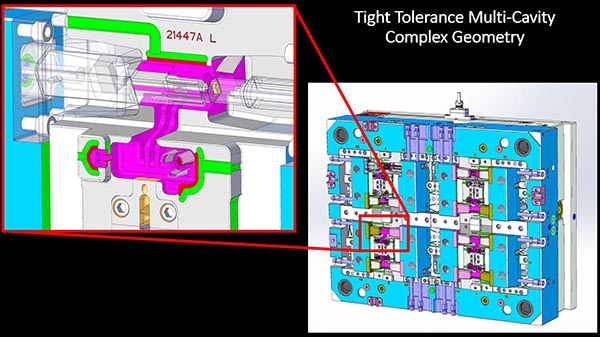

ENGINEERING/CAD CAPABILITIES

- Solid Works

- Pro/E

- AutoCAD

- Unigraphics

- IGES

- STEP

- Parasolid

- Catia