COMPANY PROFILE

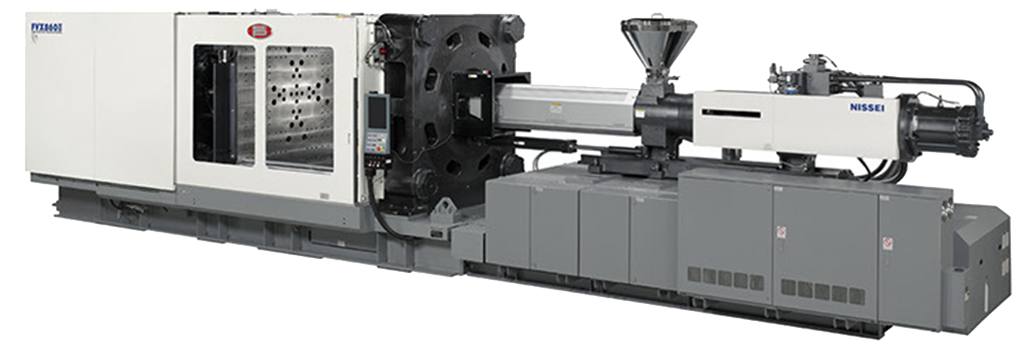

Established in 1969, Venture Plastics, Inc. (VPI) is an IATF-16949 certified custom thermoplastic injection molding company with 2 facilities; one facility located in Newton Falls, Ohio and the other in El Paso, TX. Both facilities provide a combined total of 34 injection molding machines ranging in size from 55 US tons to 1,450 US tons and has 123,000 combined square footage that is supported with IQMS integrated software system, scientific mold/ locked process/ RJG Technology, closed loop system for SPC, robotics, and centralized material handling systems. In-house maintenance capabilities exist for equipment and tooling.

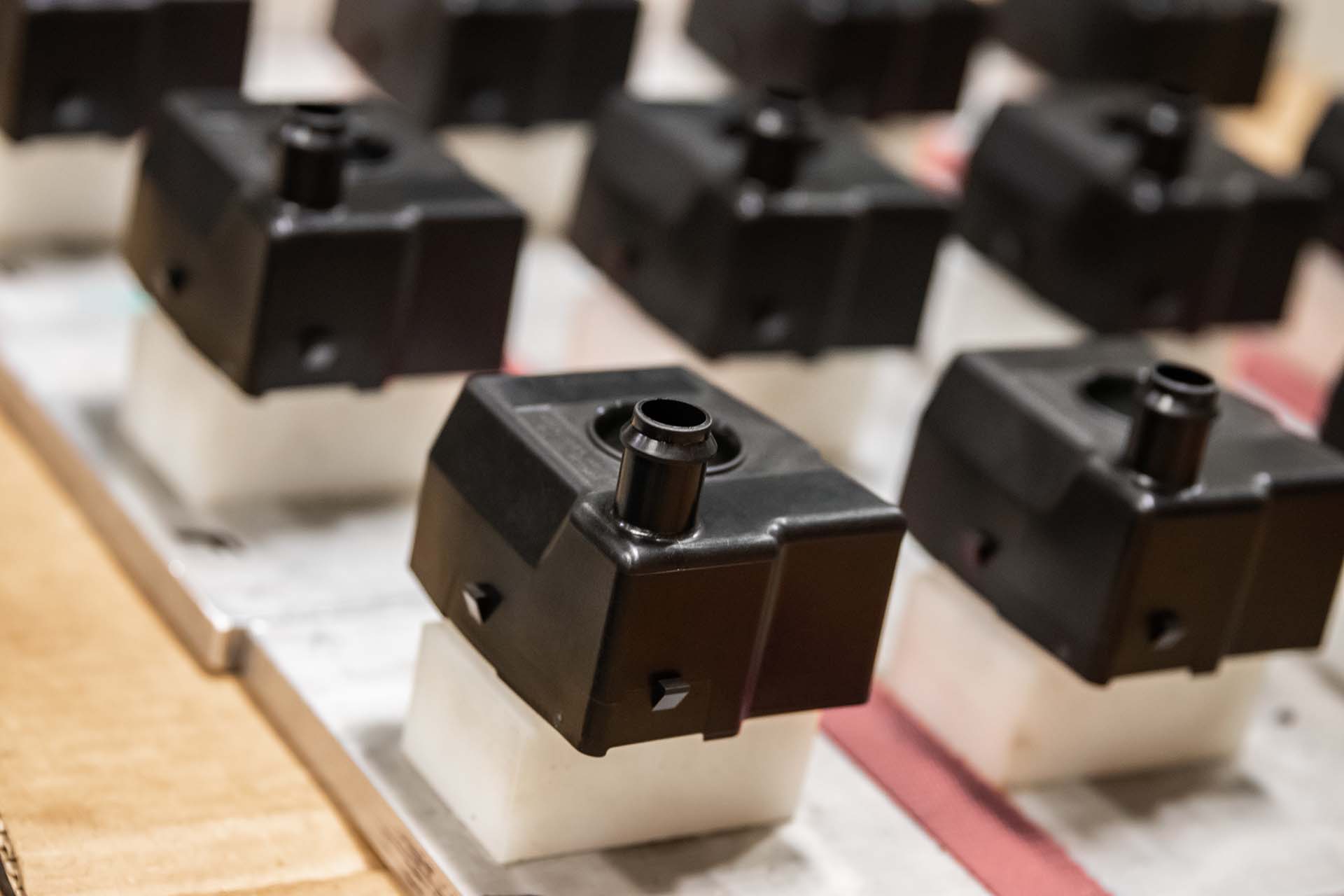

VPI’s technology and services include injection and over-molding, insert molding, complex parts, decorating/ plating, assembly/ welding, tufting processes, and a wide variety of engineered materials with UL material traceability. Scientific Molding principles are applied to assure an optimized and repeatable process on every run on every press. Scientific Molding technology can also be retrofitted to existing tools.

VPI’s engineering department readily assists customers in new product and tooling development for both molding as well as value-added processes. Engineering can work with AutoCAD, IGES/DXF, Catia, Solid Works, Pro E file transfers either through email or the use of our FTP site.

Other services provided consist of mold flow analysis, prototype service, strong program management, and global tool sources.

Venture’s major markets include Transportation, Agriculture, Appliance, Consumer, Power Back Up, Fuel Delivery, Telecommunications, Rail, Food Prep, Point of Purchase and Medical. Our customer base is very diverse in North America.

VPI’s technology and services include injection and over-molding, insert molding, complex parts, decorating/ plating, assembly/ welding, tufting processes, and a wide variety of engineered materials with UL material traceability. Scientific Molding principles are applied to assure an optimized and repeatable process on every run on every press. Scientific Molding technology can also be retrofitted to existing tools.

VPI’s engineering department readily assists customers in new product and tooling development for both molding as well as value-added processes. Engineering can work with AutoCAD, IGES/DXF, Catia, Solid Works, Pro E file transfers either through email or the use of our FTP site.

Other services provided consist of mold flow analysis, prototype service, strong program management, and global tool sources.

Venture’s major markets include Transportation, Agriculture, Appliance, Consumer, Power Back Up, Fuel Delivery, Telecommunications, Rail, Food Prep, Point of Purchase and Medical. Our customer base is very diverse in North America.

FULL SERVICE CUSTOM INJECTION MOLDER

Venture Plastics is a full service custom injection molder. We process commodity grade resins as well as highly engineered grade resins. We service many market segments and have strong purchasing with many suppliers. Our engineering department works with customers to support projects with design assist and strong project management start to finish. Scientific molding applications are utilized with the assistance of RJG technologies which provides repeatable quality production with low DPPM. Injection molding presses ranging from 55 ton up to 1,450 ton. Production excellence has been our goal for over 50 years.